Validering

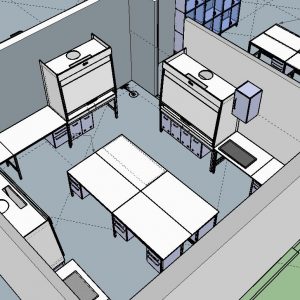

A cleanroom is a modular environment in which the following environmental factors are kept under control; temperature, airborne particulates, microbes, relative humidity, differential pressure, and air flow.

Cleanroom Validation is performed for a variety of reasons. To ensure that the design of the facility is fit for its intended purpose; to ensure that the facility, equipment, and environment meets User Requirement Specifications (URS); to ensure that the facility, equipment, and environment meet defined regulatory requirements; to ensure that the facility, equipment, and its environment function together as a system to meet defined standards.

Cleanrooms are validated and then certified to a chosen class of ISO 14644-1. Each class of ISO14544-1 has its unique requirements that must be made for a facility to be classified in the specified classification.Validation of a new cleanroom follows a specified lifecycle. The life cycle comprises five phases each of which accomplishes particular tasks to control variation in the modular environment.

Cleanroom validation work is accomplished through five phases. It starts off with the design control phase and ends with monitor and control. Changes to equipment and control factors after the cleanroom has been validated are grounds for cleanroom re-validation.

Please call you Innoguard contact to discuss or schedule validation.